What Are the Main Cost Differences in Fiber Laser Cutting Machines

What Are the Main Cost Differences in Fiber Laser Cutting Machines

You will find that fiber laser cutting machine cost changes based on several important factors. Machine type, laser power, brand reputation, and operational costs play a big role. Features like a strong laser source, advanced control system, reliable chiller, durable laser head, and high-quality laser cutting machine parts all add value. Prices range widely, as you can see below:

| Category | Price Range | Features |

|---|---|---|

| Entry-Level | $10,000 - $40,000 | Cuts thin metals, good for small businesses |

| Mid-Range | $50,000 - $100,000 | Suits medium-scale operations, balances cost/features |

| High-End | $100,000 and above | Industrial use, high power, precision |

Understanding these differences helps you make smart choices and manage your investment wisely.

Key Takeaways

- Fiber laser cutting machine costs vary based on type, power, brand, and features. Entry-level machines are cheaper, while high-end models offer advanced capabilities.

- Choose a machine that fits your specific needs. If you only cut thin materials, an entry-level model can save you money. For thicker materials, invest in a more powerful machine.

- Consider both upfront and ongoing costs. Look beyond the purchase price to include energy, maintenance, and training expenses in your budget.

- Research brands for reliability and support. Trusted brands may cost more initially but can save you money in repairs and maintenance over time.

- Prioritize essential features based on your production needs. Focus on power, work area size, and any special features that will enhance your efficiency.

Fiber Laser Cutting Machine Cost Range

Entry-Level vs. High-End Prices

You will see a wide range when you look at fiber laser cutting machine cost. Entry-level machines often start at around $15,000 for basic sheet laser models. These machines can handle thin metals and suit small workshops or new businesses. Tube laser cutters at the entry level usually cost between $30,000 and $45,000. As you move up, mid-range machines for both sheet and tube cutting can reach $150,000. High-end and industrial fiber laser cutting machines can cost $300,000 or more. Some premium models even reach $600,000, especially if you need advanced automation or high power for thick materials.

Several factors drive these price differences. Entry-level machines use lower power lasers and simpler controls. High-end machines offer more power, faster speeds, and advanced features like automatic loading or multi-axis cutting. Brand reputation and after-sales support also affect the price. You pay more for machines from well-known brands with strong service networks.

Tip: If you only need to cut thin sheets or small parts, you can save money by choosing an entry-level model. For heavy-duty or high-volume work, you may need to invest in a high-end machine.

Typical Price Examples

You can compare prices across different types and brands to get a better idea of what to expect. Here is a table showing typical price ranges:

| Type of Machine | Price Range |

|---|---|

| Entry-level sheet laser cutter | $10,000 – $50,000 |

| Mid-range sheet laser cutter | $50,000 – $150,000 |

| Industrial sheet laser cutter | $150,000 – $300,000+ |

| Entry-level tube laser cutter | $30,000 – $45,000 |

| Mainstream tube laser cutter | $45,000 – $100,000 |

| Premium tube laser cutter | $100,000 – $400,000+ |

| High-end fiber laser machine | $14,000 – $1,000,000 |

You will also find that some brands offer entry-level models like the PENDSTAR LASER EC3015 SERIES (1000W) for about $7,500. Industrial sheet metal cutters can start at $6,800, while premium machines from other brands can reach $1,000,000. The fiber laser cutting machine cost depends on your needs, the type of materials you cut, and the features you want.

Key Factors Affecting Cost

Machine Type & Configuration

You will see that the type and configuration of a fiber laser cutting machine have a big impact on price. Machines come in different types, such as entry-level, professional automatic, and industrial CNC models. Each type has its own price range and power options.

| Machine Type | Price Range | Power Options |

|---|---|---|

| Entry-level fiber laser cutter | $14,200 - $32,800 | 1500W, 2000W |

| Professional automatic fiber laser | Starting at $29,800 | 3000W, 4000W, 6000W |

| Industrial CNC fiber laser cutter | $88,000 - $500,000+ | 8000W to 60000W |

Entry-level machines cost less because they use lower power and have basic features. Professional and industrial machines cost more because they offer higher power, better automation, and advanced controls. If you need to cut thicker materials or want faster production, you will pay more for a machine with a stronger configuration.

Tip: Choose the machine type that matches your production needs. You can save money by avoiding features you do not need.

Laser Power & Capabilities

Laser power is one of the main things that affect fiber laser cutting machine cost. Higher power lets you cut thicker and tougher materials. It also increases the speed and efficiency of your work. Machines with more power cost more, but they can handle a wider range of jobs.

| Laser Power | Cutting Capacity (Carbon Steel) | Cutting Capacity (Stainless Steel) | Cutting Capacity (Aluminum) |

|---|---|---|---|

| 1kW | Up to 6mm | Up to 3mm | Up to 1.5mm |

| 1.5kW | Up to 9mm | Up to 4.5mm | Up to 2.25mm |

| 2kW | Up to 12mm | Up to 6mm | Up to 3mm |

You will find that higher laser power means higher cost, but it also means you can cut thicker materials and finish jobs faster. For example, a 1kW machine works for thin metals, while a 15kW or 20kW machine can cut thick steel at high speed. If you run a high-volume shop, investing in more power can save you time and money in the long run.

Brand & Support

Brand reputation and after-sales support also play a big role in fiber laser cutting machine cost. Well-known brands often charge more because people trust their quality and reliability. You may pay a higher price, but you get peace of mind and better service.

- Reputable brands are seen as more reliable, which raises the price.

- Good after-sales support can make a machine more valuable, as you get help with repairs and maintenance.

- Researching brands and reading reviews helps you find machines with strong support, which can save you money over time.

If you choose a lesser-known brand, you might save money at first. However, you could face higher costs later if you need repairs or cannot get parts quickly.

Features & Accessories

Extra features and accessories can add a lot to the cost of a fiber laser cutting machine. Some features make the machine easier to use or more efficient, while others improve the quality of your cuts.

- The price goes up with more features and accessories.

- Low-power machines start around $15,800, but high-power models with advanced features can cost $49,000 or more.

- Features like high-quality laser sources, advanced controllers, and energy efficiency increase the initial investment but can save money in the long run.

- Machines with low maintenance needs and high durability cost more upfront but reduce repair costs over time.

- Market demand for advanced features can also drive up prices.

| Feature/Accessory | Price Impact Description |

|---|---|

| High-Quality Laser Source | More expensive due to superior beam quality and efficiency compared to other lasers. |

| Power and Specifications | Higher power ratings lead to increased costs; advanced features add to the price. |

| Energy Efficiency | Reduces operational costs over time, offsetting higher initial costs. |

| Low Maintenance Requirements | Fewer moving parts lead to lower ongoing maintenance costs. |

| Durability | Longer lifespan justifies higher upfront costs through reduced replacement needs. |

| Market Demand | Increased demand can drive up prices, especially for advanced machines. |

| Brand Reputation | Machines from reputable brands are often priced higher due to perceived value. |

When you compare machines, look at the features you really need. You can control your fiber laser cutting machine cost by choosing only the options that help your business.

Operational & Maintenance Costs

Energy Consumption

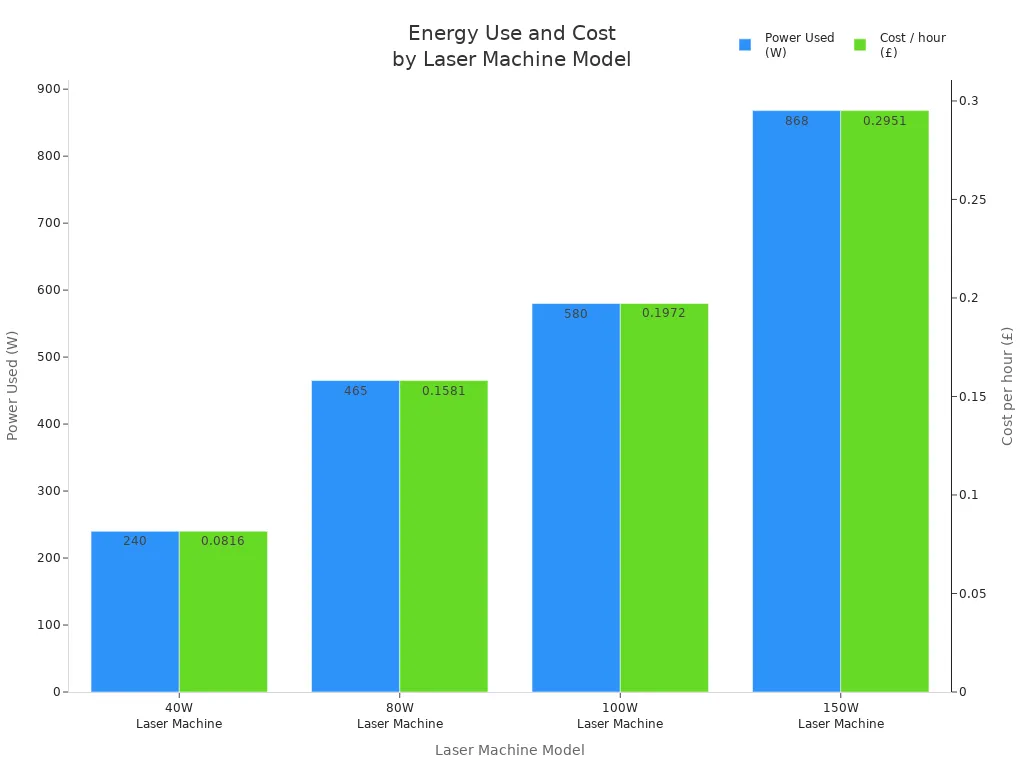

You will notice that energy use is a key part of fiber laser cutting machine costs. Different models use different amounts of power. For example, a 40W laser machine uses 240 watts, while a 150W machine uses 868 watts. The cost per hour also changes with the power level.

| Laser Machine Model | Power Used (W) | Cost / hour | Efficiency |

|---|---|---|---|

| 40W Laser Machine | 240 | $0.0816 | |

| 80W Laser Machine | 465 | $0.1581 | 18% |

| 100W Laser Machine | 580 | $0.1972 | 18% |

| 150W Laser Machine | 868 | $0.2951 | 19% |

Operational costs will vary based on how much you use the machine and the type of material you cut. High-power fiber lasers need more energy and may increase your daily expenses.

Consumables & Parts

You will need to replace certain parts and consumables regularly. These items include protective lenses, focus lenses, nozzles, and ceramic rings. Each part has a different lifespan.

| Consumable/Part | Lifetime |

|---|---|

| Protective Lens | ~1 month |

| Focus Lens | ~3 months |

| Nozzle | ~1 month |

| Ceramic Ring | ~1 year or more |

| Electric Power | 11kw/h (full power) |

| Auxiliary Gas (N2/O2) | 12kg/hour (N2 for 1mm stainless steel) |

| 9kg/hour (O2 for 5mm mild steel) |

The operational costs also include expenses for consumables such as nozzles, protective lenses, and ceramics, along with annual preventive service expenses.

Maintenance Needs

You must perform regular maintenance to keep your fiber laser cutting machine running well. Tasks include cleaning optics, checking nozzles, and scheduling deeper service. Fiber lasers need less frequent maintenance than CO2 lasers, but you still need to plan for downtime and service contracts.

High power fiber lasers require a significant amount of maintenance which will play into the cost of daily operation.

Annual maintenance costs can range from $500 to $3,000, depending on the machine and how much you use it.

| Maintenance Costs (annual) |

|---|

| 500 |

| 1,000 |

| 3,000 |

You can lower costs by following best practices:

- Regular maintenance extends machine life.

- Clean external and internal parts to prevent problems.

- Lubricate moving parts.

- Schedule professional checks for better efficiency.

Routine care helps you avoid bigger repairs and keeps your machine working smoothly.

How to Choose Based on Budget

Prioritizing Features

When you select a fiber laser cutting machine, you need to focus on the features that matter most for your work and budget. Start by thinking about what materials you want to cut and how thick they are. Power needs change based on these factors. If you plan to cut thin sheets, a lower-power machine will work. For thicker metals, you need more power.

You should also look at the working volume and speed. If you run a busy shop, a larger work area and faster cutting speed can help you finish more jobs. Think about the level of precision you need. Some projects require high accuracy, so you may want advanced controls.

It helps to make a list of your must-have features. Consider user-friendly software and strong after-sales support. These can reduce downtime and make your investment pay off faster. Here is a simple way to set your priorities:

- Decide on the power based on your main materials.

- Check the work area size and speed.

- List any special features you need, like automation or advanced controls.

- Set a clear budget, including both the machine and future costs.

Tip: Avoid focusing only on the lowest price. Machines with poor quality or weak support can cost you more in the long run.

Balancing Upfront and Ongoing Costs

You need to look beyond the sticker price. The total cost of ownership includes the purchase price, installation, energy use, maintenance, and training. High-power machines can raise your electricity bill by $2,000 to $5,000 each year. Training and software updates can also add to your expenses.

To make a smart choice, compare not just the initial cost but also what you will spend over time. Here are some things to check:

- Calculate energy and maintenance costs for each machine.

- Ask about training fees and software licenses.

- Look for financing options if you want to spread out payments.

- Think about how a reliable machine can boost your production and lower repair costs.

Many buyers make mistakes by ignoring these ongoing costs or choosing machines with poor support. You can avoid surprises by planning for all expenses. This approach helps you pick a machine that fits your budget and supports your business growth.

| Buyer Type | Budget Range | Key Needs |

|---|---|---|

| Hobbyists | Under $2,000 | Safety, ease of use |

| Small Businesses | $2,000 - $15,000 | ROI, efficiency, expandability |

| Industrial Users | $15,000 and above | Precision, 24/7 production |

You now know what drives the cost differences in fiber laser cutting machines. The table below highlights what factors impact price:

| Key Consideration | Impact on Cost |

|---|---|

| Material Type | Different machines suit different materials |

| Thickness | Thicker materials need more powerful machines |

| Production Volume | High volume justifies higher investment |

| Machine Power | More power means higher price and better results |

| Supplier Support | Good support lowers long-term costs |

- Fiber lasers cut fast and handle many metals.

- They need less maintenance, which lowers your costs.

- You should match machine features to your needs and budget.

- Always consider both the purchase price and ongoing expenses.

Choosing the right machine helps you save money and boost productivity.

FAQ

What is the main factor that affects fiber laser cutting machine cost?

You will find that laser power is the main factor. Higher power lets you cut thicker materials and work faster. This increases the price. Other factors include machine type, brand, and extra features.

What should you look for when comparing machine brands?

You should check for strong after-sales support, good reviews, and a reliable service network. Trusted brands often cost more, but they offer better help and fewer problems.

What ongoing costs should you expect?

You will need to pay for energy, replacement parts, and regular maintenance. These costs depend on how much you use the machine and the materials you cut.

What materials can fiber laser cutting machines handle?

You can cut metals like carbon steel, stainless steel, and aluminum. The machine’s power decides the thickness you can cut. Always check the specifications before buying.