Beginner’s Guide to Retrofitting Old Cutting Machines to Fiber Laser Cutters

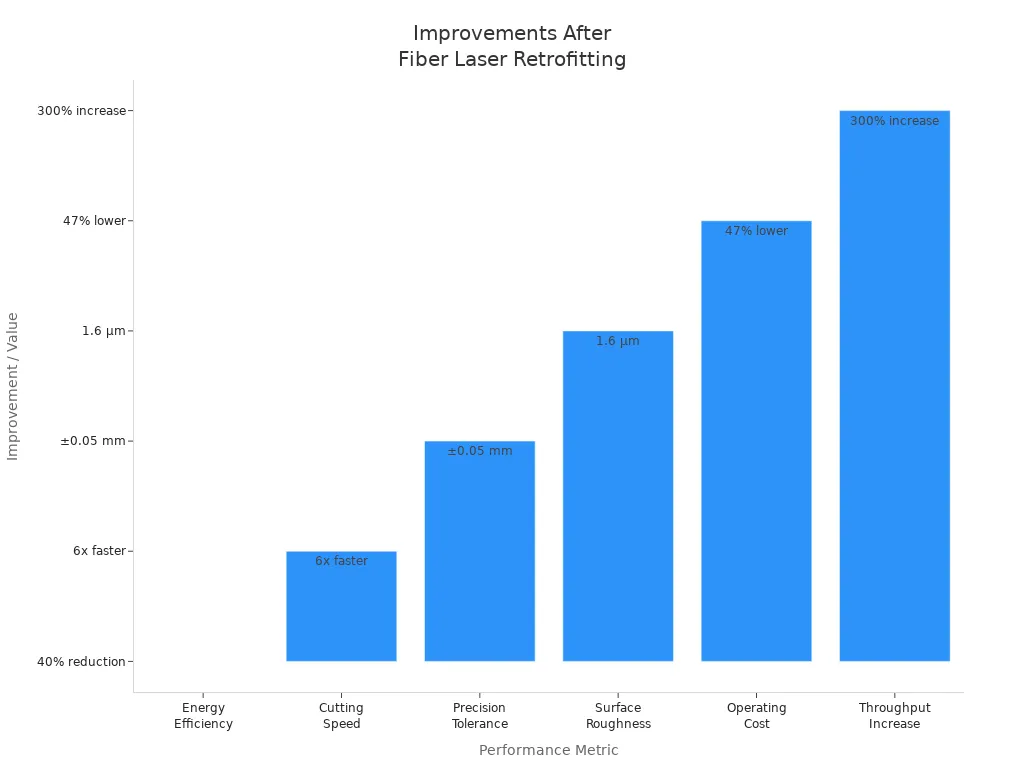

You can retrofit to Fiber laser cutting machine technology and achieve a dramatic boost in your shop’s performance. With modern Fiber Laser Parts—like a high-efficiency Fiber laser source, advanced Fiber Laser head, and an upgraded Laser Control system—you unlock exceptional precision, speed, and energy savings. Many manufacturers report up to 40% lower energy use and triple the throughput after upgrading.

A trusted Laser parts supplier such as Pendstar Laser can guide you through the process, using expertise gained from real-world retrofits and machine building.

Key Takeaways

- Retrofitting old cutting machines to fiber laser technology boosts speed, precision, and energy efficiency, improving shop performance.

- CO2 laser cutters and some plasma cutters are good retrofit candidates; CNC routers need careful evaluation due to technical challenges.

- Fiber laser retrofits save energy, reduce maintenance, and cut a wide range of materials but require upfront investment and strict safety measures.

- The retrofit process involves removing old parts, installing fiber laser components, upgrading controls, and ensuring safety compliance.

- Proper training, regular maintenance, and expert support help you achieve a successful retrofit and maximize your return on investment.

Can You Retrofit to Fiber Laser Cutting Machine?

Upgrading your old cutting machine to a fiber laser system can transform your production capabilities. Before you start, you need to know which machines are suitable for retrofitting, what benefits and challenges you might face, and when this investment makes the most sense for your business.

Which Machines Can Be Retrofitted

You can retrofit several types of cutting machines to fiber laser technology. The most common candidates include:

- CO2 Laser Cutters: These machines often have robust frames and motion systems. You can remove the old CO2 laser tube and optics, then install a fiber laser source, head, and chiller. Many shops have successfully upgraded Bystar and Trumpf CO2 machines to fiber laser systems.

- Plasma Cutters: Some plasma cutting tables can be adapted for fiber laser use, especially if they have precise motion control and a sturdy frame. However, you may need to upgrade the control system and add safety features.

- CNC Routers: Retrofitting a CNC router is possible, but it comes with more technical challenges. The frame and motion system may not support the speed and precision required for fiber laser cutting. You must also address significant safety risks.

Tip: Not all machines are good candidates. Machines with worn-out frames, outdated controls, or poor motion accuracy may not justify the investment. Always assess the condition of your equipment before starting a retrofit to Fiber laser cutting machine.

Benefits and Drawbacks

When you retrofit to Fiber laser cutting machine technology, you unlock several advantages:

| Benefit | Description |

|---|---|

| Precision | Fiber lasers deliver clean, accurate cuts with minimal heat-affected zones. |

| Speed | You can cut thin and medium-thick metals up to three times faster. |

| Energy Efficiency | Fiber lasers use up to 50% less power than CO2 lasers. |

| Lower Maintenance | Solid-state design means fewer moving parts and less downtime. |

| Versatility | Cut a wide range of metals and some plastics with one machine. |

| Environmental Impact | Reduced energy use and no need for laser gases lower your carbon footprint. |

However, you should also consider the main drawbacks:

- Upfront Cost: The initial investment for a fiber laser source, head, chiller, and controls can be significant.

- Complexity: The retrofit process requires technical skill and careful planning.

- Safety: High-power fiber lasers demand strict safety measures, including enclosures, interlocks, and fume extraction.

Many companies, such as those using Bystar, Trumpf, and Eagle machines, have reported major gains after retrofitting. They achieved higher throughput, better cut quality, and lower operating costs.

When a Retrofit Makes Sense

You should consider a retrofit to Fiber laser cutting machine when your business is growing and you need to boost production speed and quality. This upgrade works best if you want to:

- Expand your product offerings with cleaner, more precise cuts.

- Attract new clients by delivering higher quality and faster turnaround.

- Reduce labor costs by minimizing secondary finishing and manual work.

- Lower operational expenses through energy savings and less material waste.

- Take on more complex jobs with automation and consistent results.

Retrofitting makes the most sense when you have already maximized your current machine’s capabilities and want to move into new markets or increase your capacity. Always evaluate the upfront cost, impact on cash flow, and potential for new business. Calculate your return on investment by considering additional work, client growth, and operational savings.

Note: Pendstar Laser offers a one-stop solution for fiber laser parts from top brands like Raycus, Max, IPG, RECI, BWT, RAYTOOLS, and BOCHU. With experience in both machine building and retrofitting, you can rely on their expertise to guide your upgrade project.

Retrofit Process Overview

Retrofitting your old cutting machine to fiber laser technology involves several critical steps. You need to remove outdated components, install new fiber laser parts, upgrade control systems, and implement strict safety measures. This process transforms your equipment, boosts productivity, and ensures compliance with modern standards.

Disassembly and Preparation

Begin by assessing your existing machine for compatibility. You should inspect the frame, motion system, and control electronics. Remove the old CO2 laser source, cutting head, and water chiller. Clear the workspace and disconnect all accessories. Prepare the mounting points for new hardware.

Tip: Label all wires and connectors during disassembly. This step helps you avoid confusion when installing new components.

You must also upgrade several critical parts to support the retrofit to Fiber laser cutting machine technology:

- Control box designed for CO2 to fiber laser transition

- Z-axis height adjustment box for precise cutting head positioning

- Focus control box to maintain correct focal point

- Upgrade materials such as drag chains and mounting plates

Installing Fiber Laser Components

Next, install the fiber laser source, cutting head, and water chiller. These components replace the old CO2 laser parts and deliver higher efficiency and precision. You need a controller box to interface signals between the CNC system and the new fiber laser modules.

Recommended brands for fiber laser sources include Max, Raycus, and RECI. Many retrofit projects use these brands for reliable performance.

Pendstar Laser provides a one-stop solution for fiber laser parts from famous brands like Raycus, Max, IPG, RECI, BWT, RAYTOOLS, and BOCHU. Their experience in machine building, retrofitting, and repairs ensures you receive expert guidance and high-quality components.

Control and Software Upgrades

Upgrading your control system and software is essential for optimal fiber laser performance. You must replace existing control boards with ones compatible with fiber laser modules.

Configure your CNC machine parameters to switch from router or plasma mode to laser mode. For example, set parameter 32 from 0 to 1. Install or update laser control software such as Cypcut. This software recognizes fiber laser modules and supports features like air assist.

| Upgrade Category | Typical Upgrades and Requirements |

|---|---|

| Software Upgrades | Adjust CNC parameters, configure laser control software, update drivers, integrate advanced digital controls |

| Control System Upgrades | Replace control boards, integrate automation modules, ensure Industry 4.0 compatibility |

| Integration and Maintenance | Configure automated setup, intelligent monitoring, regular calibration, assess CAD/CAM compatibility |

You should also integrate automation modules for material handling and ensure compatibility with Industry 4.0 technologies. Regular calibration and maintenance keep your system running smoothly.

Safety and Compliance

Safety is the top priority when you retrofit to Fiber laser cutting machine technology. High-power lasers require strict safety protocols.

Install enclosures and interlocks to prevent accidental exposure to the laser beam. Use fume extraction systems to remove hazardous fumes and particulates. Position extraction nozzles close to the cutting area for maximum effectiveness.

Maintain proper ventilation to create a clean workspace. Select fume extractors based on airflow needs and filter types. Change filters and inspect systems regularly.

You must wear personal protective equipment such as N95 masks or respirators. Regular testing ensures safety systems like interlocks, beam controls, and protective barriers work correctly. Inspect emergency shutdowns and access controls often.

Note: These safety measures help you comply with OSHA regulations and protect operator health.

Pendstar Laser’s expertise in retrofitting and repairs includes guidance on safety upgrades. Their support helps you achieve a safe, compliant, and efficient retrofit.

Special Case: CNC Router Retrofit

Technical Challenges

Retrofitting a CNC router to a fiber laser cutter presents significant technical hurdles. You must replace the spindle with a high-power fiber laser source, which demands advanced mechanical and electronic upgrades. Fiber laser cutters require precise motion control and high-speed operation. Most CNC routers use standard rack and pinion drives and basic linear guides, which do not support the accuracy or speed needed for fiber laser cutting. You would need to upgrade to helical rack and pinion transmissions and premium linear guides, such as TBI, to achieve stable performance. The drive system, control electronics, and overall machine construction often need extensive modification. These upgrades can make the retrofit more expensive and complex than purchasing a dedicated fiber laser cutter. In many cases, the final machine may not match the stability or effectiveness of a purpose-built fiber laser system.

Tip: Before starting a retrofit, evaluate your CNC router’s frame, motion system, and control board. If these components cannot support fiber laser technology, consider alternative solutions.

Safety Risks

Fiber laser retrofits introduce serious safety concerns. High-power lasers can cause eye injuries, skin burns, and release hazardous fumes. You must install a fully enclosed cutting area, interlocks, and robust fume extraction to protect operators. Specialized safety glasses are mandatory. Most CNC routers lack these features, so you need to add them during the retrofit. Without proper safety upgrades, you risk accidents and non-compliance with safety regulations.

| Safety Feature | Why It Matters |

|---|---|

| Enclosure | Prevents accidental laser exposure |

| Interlocks | Shuts down laser if access is detected |

| Fume Extraction | Removes harmful fumes and particulates |

| Protective Eyewear | Shields eyes from laser radiation |

Alternative Options

If you want to add laser capabilities to your CNC router, safer and more cost-effective alternatives exist:

- Diode Laser Module: Install a low-power diode laser for engraving and light cutting. This option is affordable and suitable for non-metal materials.

- CO2 Laser Module: Attach a CO2 laser module for cutting thicker wood and acrylics. You gain more power for soft materials, but cannot cut metals.

- Dedicated Fiber Laser Machine: Purchase a purpose-built fiber laser cutter. You get integrated safety features, optimized software, and reliable performance for metal cutting.

Pendstar Laser offers a wide range of fiber laser parts from leading brands, including Raycus, Max, IPG, RECI, BWT, RAYTOOLS, and BOCHU. As a manufacturer and retrofit expert, Pendstar Laser can help you select the best solution for your workshop, whether you choose a retrofit or a new machine.

Note: Consider your budget, safety requirements, and desired cutting capabilities before deciding on a retrofit or alternative upgrade.

Special Case: CO2 Retrofit

Technical Challenges

When you retrofit a CO2 cutting machine to fiber laser technology, you face several technical hurdles. You must remove the old CO2 laser tube, optics, and cooling system. The frame and motion system need to support the higher speeds and precision of fiber lasers. You often need to upgrade the control electronics and software to handle the new laser source. Many CO2 machines use different mounting systems, so you may need custom brackets or plates for the fiber laser head. You should check the compatibility of your existing CNC controller with fiber laser modules. Pendstar Laser offers a wide selection of fiber laser parts from top brands, making it easier for you to find components that fit your retrofit project.

Tip: Before starting, inspect your machine’s frame, motion system, and electronics. Make sure they can handle the demands of fiber laser cutting.

Safety Risks

Fiber laser retrofits introduce new safety risks that you must address. Fiber lasers emit invisible near-infrared beams, which can cause severe eye injuries, including retinal burns and permanent vision loss. Unlike CO2 lasers, fiber lasers can harm you even through indirect exposure or reflections. Inconsistent safety features among machines, especially budget models, increase the risk of accidents. Regulatory standards like OSHA and ANSI require safety interlocks, protective eyewear, and controlled work areas.

- Bypassing safety interlocks can result in equipment damage and operator injury.

- Overriding water flow detectors risks overheating and damaging the laser tube.

- Accessing electronics during operation exposes you to dangerous high voltages.

- Placing materials or body parts in the beam path can cause fires and permanent damage.

- Obstructing the moving axis with materials can lead to mechanical collisions and misalignment.

- Axis limit switches must remain unobstructed to prevent machine damage.

Note: Always use proper enclosures, interlocks, and fume extraction systems. Wear certified protective eyewear when working near fiber lasers.

Alternative Options

If you want to upgrade your CO2 cutting machine, you have two main options:

- Replace the CO2 laser with a fiber laser system for maximum efficiency and speed.

- Add a fiber laser system alongside your existing CO2 laser to expand capabilities.

Fiber lasers reduce operating costs by up to 80% and cut thinner materials up to four times faster than CO2 lasers. You can process reflective metals like copper, aluminum, and brass without damage risks. Fiber lasers also require less space due to their compact design. If you work with both thick and thin materials, adding a fiber laser to your setup can optimize performance and cost efficiency. Companies like Alpha Lazer support the upgrade process with installation, training, and technical support.

Pendstar Laser provides expert guidance and high-quality fiber laser parts, helping you achieve a successful retrofit or upgrade with minimal downtime.

Key Considerations

Cost and ROI

When you plan a retrofit to Fiber laser cutting machine, you need to understand the investment and potential returns. The cost for a typical retrofit set ranges from $19,000 to $39,000. This includes the fiber laser source, cutting head, water chiller, controller box, and other essential parts. Most suppliers offer a two-year warranty for the laser source and a one-year warranty for the head and chiller. Installation usually takes 7-10 days with on-site training.

| Aspect | Details |

|---|---|

| Retrofit Cost Range | US$3000 to US$15000 per retrofit set, according to the power range |

| Main Parts Required | Fiber Laser Source, Fiber Laser Head, Water Chiller, Controller Box, Drag Chains, etc. |

| Warranty | 2 years for laser source; 1 year for laser head and chiller |

| Installation & Training | Engineer sent to client factory for 7-10 days |

Return on investment (ROI) depends on your automation level and production needs. Many small and medium manufacturers see ROI within 1-3 years, especially when energy savings and reduced maintenance are factored in.

Required Skills

You need a mix of technical and operational skills to complete a successful retrofit. These include:

- Operator training on machine operation, laser principles, and safety.

- Machine setup and calibration, such as aligning the cutting head and adjusting focus.

- Maintenance skills for cleaning, calibration, and cooling system checks.

- Understanding material compatibility and adjusting laser settings.

- Process optimization for different materials and thicknesses.

- Quality control and testing for precision.

- Integrating new systems into your workflow, including software updates.

Pendstar Laser provides expert support and guidance, helping you build these skills during installation and training.

Maintenance Needs

Ongoing maintenance keeps your retrofitted fiber laser cutter running smoothly. You should:

- Clean exterior and interior parts regularly to remove dust and debris.

- Monitor the cooling system by checking coolant levels and replacing dirty coolant.

- Inspect and clean optics, such as lenses and mirrors, to maintain cut quality.

- Perform routine alignment and calibration based on manufacturer guidelines.

Regular maintenance extends machine life and ensures consistent performance.

Training for Beginners

If you are new to retrofitting, many resources can help you get started:

- Step-by-step blog posts on retrofitting popular machines like Amada, Trumpf, and Bystronic.

- DIY guides for building fiber metal tube laser cutters.

- Fiber laser repair courses and books.

- Q&A forums and support packages for DIY projects.

- Community support and technical insights tailored for beginners.

Pendstar Laser offers training and support, drawing on years of experience in machine building and retrofitting. You can rely on their expertise to guide your first retrofit to Fiber laser cutting machine.

When you retrofit to Fiber laser cutting machine technology, you unlock faster production, higher precision, and lower maintenance. Experts recommend that you learn the differences between CO2 and fiber lasers, focus on proper setup, and practice parameter tuning for best results. Many users report streamlined automation, material savings, and improved safety. Before starting, weigh your goals, budget, and safety needs. For guidance, consult experienced suppliers like Pendstar Laser, who offer both parts and technical support. Upgrading your equipment can future-proof your business and drive long-term success.

FAQ

What types of machines can you retrofit to fiber laser technology?

You can retrofit CO2 laser cutters, plasma cutters, and some CNC routers. Always check your machine’s frame and motion system for compatibility before starting. Pendstar Laser offers expert advice on selecting suitable machines for retrofitting.

How long does a typical fiber laser retrofit take?

Most retrofits require 7 to 10 days for installation and training. You receive on-site support from experienced engineers. Pendstar Laser provides guidance throughout the process to ensure a smooth upgrade.

What safety measures should you follow during a retrofit?

You must install enclosures, interlocks, and fume extraction systems. Always wear certified protective eyewear. Pendstar Laser recommends regular safety checks and offers support for compliance with industry standards.

Can you use your existing CNC software after retrofitting?

You can often use your current CNC software with minor modifications. You may need to update parameters and install compatible laser control software. Pendstar Laser supplies integration support for software upgrades.

Which brands of fiber laser parts does Pendstar Laser supply?

Pendstar Laser supplies parts from Raycus, Max, IPG, RECI, BWT, RAYTOOLS, and BOCHU. You can access a wide range of components for retrofitting and repairs, backed by expert technical support.