How to Protect Your Fiber Laser Cutting Machine from Winter Freezing

Winter temperatures can quickly damage your fiber laser cutting machine if you do not prepare. Freezing water in the cooling system can crack pipes and ruin sensitive components. You can avoid costly repairs by taking fast, effective steps.

Act now to keep your equipment safe and reliable. Use heaters, monitor room temperature, and check your system daily. These actions protect your investment and keep your production on track.

Key Takeaways

- Maintain a warm workshop temperature between 18°C and 21°C to prevent freezing in the cooling system.

- Run the chiller continuously, even when the machine is idle, to keep water moving and avoid ice formation.

- Drain all coolant from the system if the machine will be idle for more than three days to prevent damage from freezing.

- Use laser-specific antifreeze with a freezing point at least 5°C lower than the expected lowest temperature for safe operation.

- Conduct weekly maintenance checks to monitor temperature, inspect for leaks, and ensure proper lubrication of moving parts.

You must keep your workshop warm to protect your fiber laser cutting machine during winter. Cold air can cause water in the cooling system to freeze. This can damage pipes and lower the quality of your cuts. Most manufacturers recommend keeping the workshop between 18°C and 21°C (64°F to 70°F). Never let the temperature drop below 50°F. Warmer air helps your machine run smoothly and prevents sudden breakdowns.

A stable temperature does more than prevent freezing. It keeps the cooling system working well. Water cooling units remove heat from the machine. If the room gets too cold or too hot, the cooling system cannot do its job. This can lead to poor cutting quality or even safety risks. You want smooth, neat edges on your materials. You also want your equipment to last as long as possible.

To keep your workshop at the right temperature, use these practical solutions:

- Place space heaters near your machine to keep the area warm.

- Insulate walls and doors to stop heat from escaping.

- Use a dehumidifier to reduce moisture and prevent rust.

- Clean out water from the system often to avoid ice buildup.

You should also monitor the temperature at all times. The following tools help you track conditions and react quickly:

| Monitoring Device | How It Helps |

|---|---|

| Thermocouples | Give accurate readings at key points |

| Infrared Sensors | Check temperatures without touching moving parts |

Install these devices on important parts of your fiber laser cutting machine. This reduces downtime and helps you spot problems before they get worse.

Tip: Check for ice or snow around your machine every day. Lubricate moving parts to keep them from freezing.

By following these steps, you create a safe environment for your equipment and avoid costly repairs.

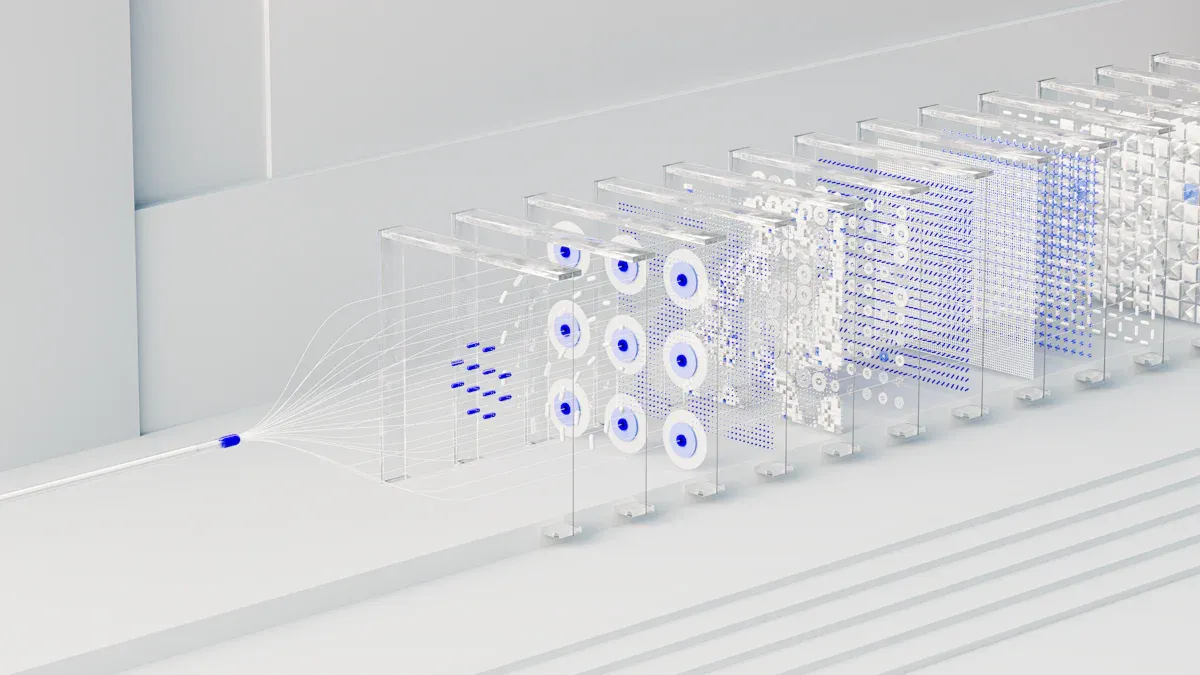

Fiber Laser Cutting Machine Cooling System

Continuous Chiller Operation

You must keep the chiller running, even when your fiber laser cutting machine is not in use. This step prevents water in the cooling system from freezing and protects all internal parts. When you let the chiller operate continuously, the cooling water keeps moving. This movement stops ice from forming inside pipes and components.

Keeping the water chiller running continuously, even when the machine is idle, prevents water in the cooling system from reaching the freezing point and avoids temperature fluctuations.

Here are the main benefits of continuous chiller operation:

- The chiller keeps temperatures stable.

- Water in the cooling system does not reach freezing temperatures.

- The system experiences less thermal stress, which helps parts last longer.

Research by the Laser Institute of America shows that effective cooling can reduce overheating errors by up to 70%. This means your fiber laser cutting machine will perform better and last longer if you keep the chiller running.

Adjusting Water Temperature

You need to set the chiller to the right temperature during winter. If the water is too cold, it can freeze. If it is too warm, the machine may overheat. The best practice is to keep the low-temperature setting between 68°F and 75°F and the high-temperature setting between 82°F and 86°F.

| Chiller Setting | Recommended Temperature (°C) |

|---|---|

| Low Temperature | 20-24 |

| High Temperature | 28-30 |

The ideal room temperature for your laser is around 22°C. Before you start the machine, let the chiller run for at least 20 minutes. This step ensures the coolant reaches the set temperature and protects the system from sudden temperature changes.

- Always check the water temperature before starting your fiber laser cutting machine.

- If you notice any sudden drops in temperature, inspect the chiller and coolant for problems.

Draining Coolant During Downtime

If you plan to leave your fiber laser cutting machine idle for more than three days or during long breaks, you must drain all coolant from the system. Water left inside can freeze, expand, and cause serious damage. Cracks may form in cooling plates, pipes, and joints. Freezing can also lead to leaks, electrical problems, and even damage to the laser optics.

Follow these steps to drain water from all components:

- Unscrew the filter element in the chiller to drain water from the filter.

- Open the tank cover and check the water level. If water remains, use compressed air to blow back the water supply port.

- Let the laser pipe and pump return water to the tank, then drain it through the tank drain.

- Tilt the cooler slightly or use a dry towel to remove any leftover water.

- Drain the cooling water from the fiber laser source, laser head, and water chiller after each use.

- Open the drain to empty the water tank.

- Use plugs to block the OUTLET(H), INLET(H), and INLET(L), then open the water supply inlet.

- Blow the OUTLET(L) and OUTLET(H) with compressed air for 80 seconds each, then block them with plugs.

- Blow the water supply inlet until no water droplets come out.

Tip: Always check for water in every part of the cooling system, including the chiller, laser, cutting head, and lens. Even a small amount of water can freeze and cause damage.

By following these steps, you protect your fiber laser cutting machine from ice damage and avoid expensive repairs. Regular draining and careful temperature control keep your equipment safe all winter.

Antifreeze for Fiber Laser Cutting Machines

Choosing the Right Antifreeze

Selecting the correct antifreeze is essential for protecting your fiber laser cutting machine during winter. You should always pick an antifreeze with a freezing point at least 5°C lower than the lowest temperature your workshop might reach. This extra margin keeps your cooling system safe, even in unexpected cold snaps.

Here are the main criteria you should consider:

- Freezing point at least 5°C below your lowest expected temperature.

- Strong anti-corrosion and anti-rust properties.

- Compatibility with rubber sealing tubes to prevent swelling or corrosion.

- Low viscosity at cold temperatures for smooth flow.

- Stable chemical properties for long-term use.

| Criteria | Description |

|---|---|

| Freezing Point | At least 5°C lower than the coldest temperature your machine will face. |

| Performance | Must prevent rust and corrosion, and not damage rubber seals. |

| Viscosity | Should stay thin enough to flow easily in cold weather. |

| Chemical Stability | Needs to remain stable and not break down over time. |

| Application | Some lasers require deionized water, so check your machine’s requirements. |

Proper Mixing and Use

You should always use antifreeze designed for laser equipment. Brands like Clariant’s Antifrogen N work well when mixed at a ratio of 3 parts antifreeze to 7 parts distilled or deionized water. This blend protects your system down to -20°C. Never use automotive antifreeze, as it can increase electrical conductivity and damage your machine.

- Mix antifreeze and water before adding to the cooling system.

- Flush the system with deionized water after winter ends.

- Follow the manufacturer’s guidelines for storage and operation.

Tip: Antifreeze is not a permanent replacement for distilled water. Only use it during cold months.

Safety and Compatibility Tips

You must handle antifreeze with care. Some types, like ethylene glycol, are toxic and require gloves and eye protection. Propylene glycol is safer but still needs careful handling. Always check the safety data sheet for your chosen product.

| Antifreeze Type | Description | Safety Profile |

|---|---|---|

| Ethylene Glycol (EG) | Effective but toxic; handle and dispose of carefully. | Toxic, use PPE. |

| Propylene Glycol (PG) | Less toxic, safer for most users. | Safer, but still use with care. |

| Laser-specific blends | Designed for laser systems, often safer to use. | Generally safe if used properly. |

Never use undiluted automotive antifreeze. It can cause electrical problems and damage rubber or plastic parts inside your fiber laser cutting machine. Always choose products made for laser equipment to ensure safety and reliability.

Winter Maintenance Tips

Weekly Maintenance Checks

You need to check your fiber laser cutting machine every week during winter. These checks help you catch problems early and keep your equipment running smoothly. Start by making sure the ambient temperature stays above 0°C. This prevents freezing and keeps the cooling system working. Keep the chiller running at all times. This step stops water from freezing inside the pipes. After each day, empty the cooling water to avoid ice buildup. Regular checks and servicing minimize disruptions and reduce wear on your machine. You also prevent breakdowns and maintain high-quality cuts.

- Maintain room temperature above freezing.

- Run the chiller continuously.

- Drain cooling water daily.

- Inspect for leaks or ice.

- Check antifreeze levels.

Tip: Set a reminder for weekly inspections to avoid missing any steps.

Lubrication in Cold Weather

Cold weather can make moving parts stiff and slow. You must use the right lubricants to keep guide rails and drive trains working well. Avoid grease because it attracts dust and debris. Choose low-temperature lubricants for effective protection. Dry lubricants, such as PTFE-based products, do not attract dirt. Low-viscosity oils like WD40, motorcycle engine oil, or car engine oil work well in cold conditions. Lubricate guide rails and racks every day to maintain smooth movement and precise cutting. Regular lubrication extends the life of your machine’s moving parts.

- Use low-temperature lubricants.

- Apply dry lubricants to avoid dust buildup.

- Lubricate daily for best results.

Professional Inspection and Emergency Steps

Schedule professional maintenance before winter starts. Technicians can clean optics, replace nozzles, service chillers, and check alignment. These steps prevent unexpected breakdowns and extend your machine’s lifespan. If you suspect freezing, follow emergency procedures:

| Step | Action | Description |

|---|---|---|

| 1 | Raise Room Temperature | Keep the area above 0°C. |

| 2 | Power On Equipment | Run the laser and chiller to circulate water. |

| 3 | Drain All Water | Remove water from cooling system and pipes. |

| 4 | Use Compressed Air | Blow out residual water from tanks and hoses. |

| 5 | Inspect for Damage | Check for cracks or leaks before restarting. |

Note: For special chillers, bleed the water pump after refilling to prevent damage.

Regular winter maintenance saves money by preventing breakdowns and keeping your fiber laser cutting machine in top condition.

You can protect your fiber laser cutting machine from winter damage by following these key steps:

- Keep your workshop warm and use insulation to prevent freezing.

- Drain cooling water and store your machine in a dry place during downtime.

- Check for moisture, ice, or leaks every week.

- Use laser-specific antifreeze for safe de-icing.

Stay proactive with regular checks and consult professionals for complex issues. This approach helps you avoid downtime and costly repairs.

FAQ

What should you do if your fiber laser cutting machine freezes?

Turn off the machine. Raise the room temperature above freezing. Drain all water from the cooling system. Use compressed air to clear pipes. Inspect for cracks or leaks before restarting. Call a technician if you find damage.

Can you use regular car antifreeze in your laser cooling system?

No, you should not use car antifreeze. It can damage seals and increase electrical conductivity. Always choose antifreeze made for laser equipment. This protects your machine and keeps it running safely.

How often should you check the coolant and antifreeze levels?

You should check coolant and antifreeze levels every week during winter. Regular checks help you spot leaks or low levels early. This keeps your cooling system working and prevents freezing.

What temperature should you set for the chiller in winter?

Set the chiller’s low temperature between 20°C and 24°C. Set the high temperature between 28°C and 30°C. These settings keep the coolant from freezing and protect your machine.

Why is daily lubrication important in cold weather?

Cold weather makes moving parts stiff. Daily lubrication keeps guide rails and drive trains smooth. Use low-temperature or dry lubricants. This prevents wear and ensures accurate cutting.